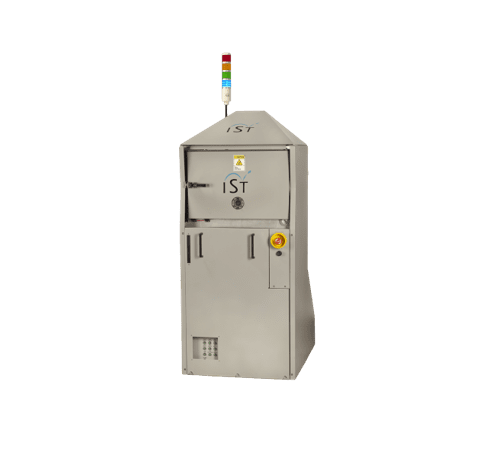

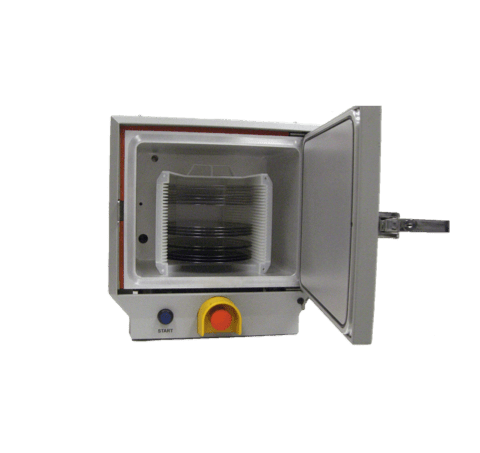

The RPX-210 system is extremely compact and is intended to fit on a bench top workstation with a remote facility box to supply additional facilities. The RPX-210 system is ideal for silanation reactions on bio-consumables or wafers. With IST’s Vaporrix cartridges and chemistry can exchange in as little as 15 minutes.

- 20-liter chamber (Capacity Reference: one 200mm Wafer Cassette).

- 2 Liquid precursors.

- 2 Gas sources (O2, N2, or Ar).

- 100W Plasma Source.

- Solid Block Aluminum chamber. Corrosion Proof.

- Superior Thermal Uniformity.

- CE Mark.