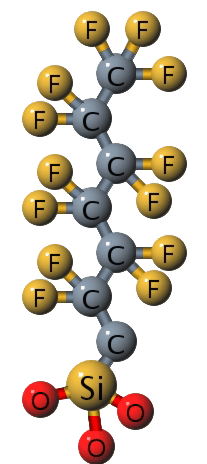

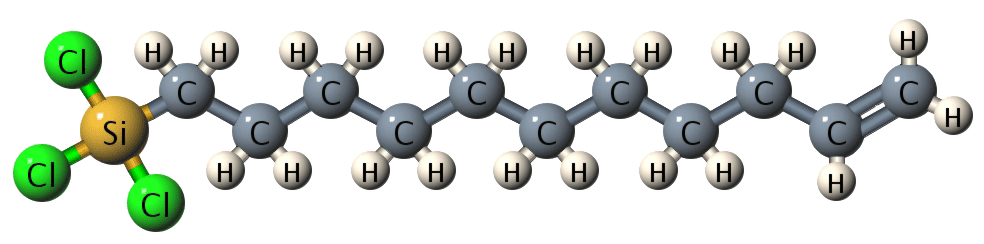

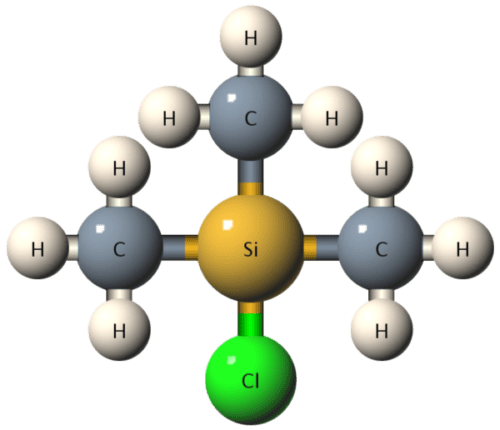

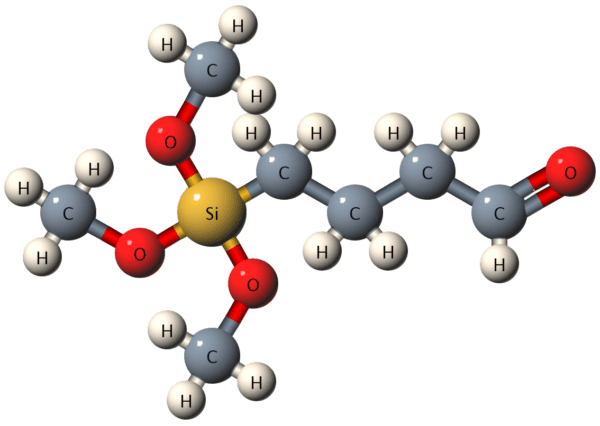

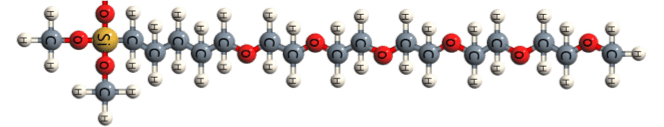

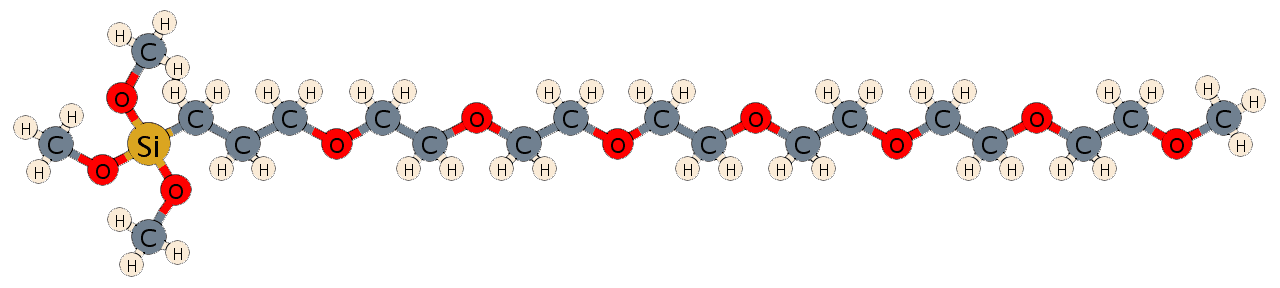

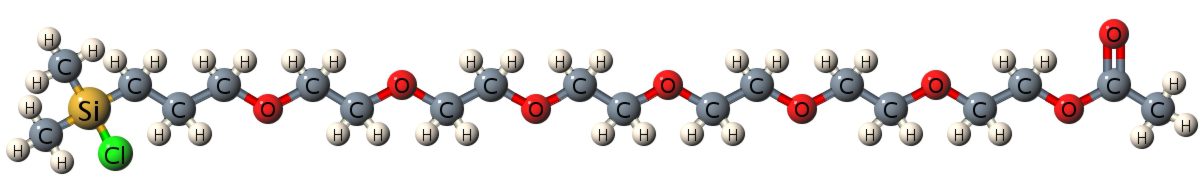

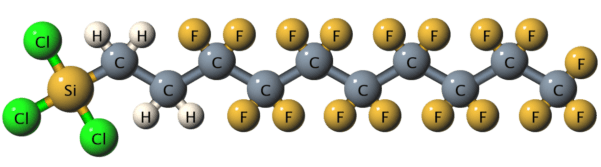

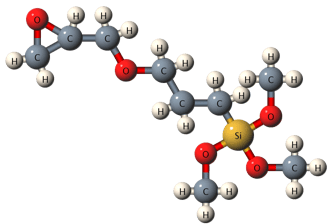

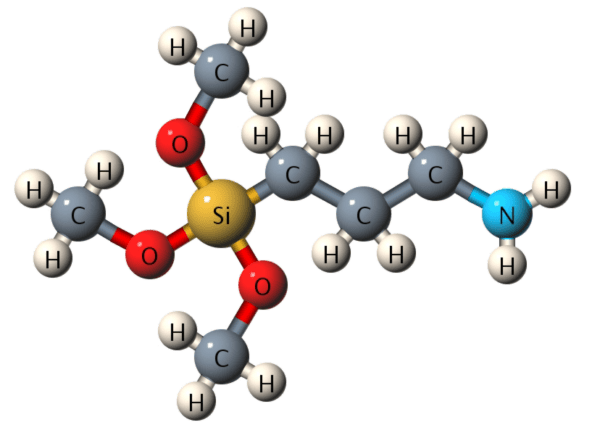

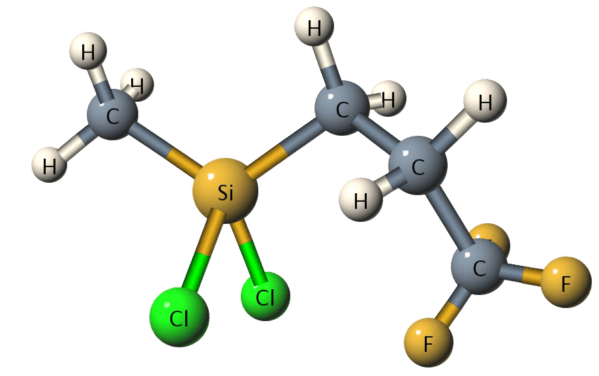

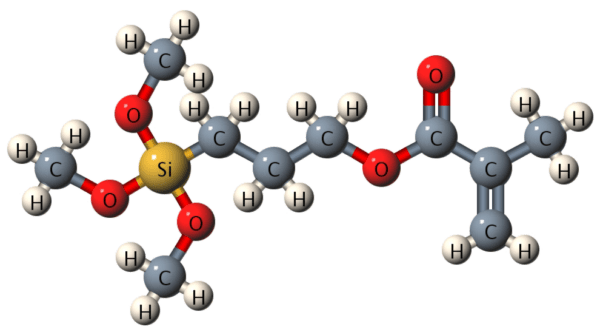

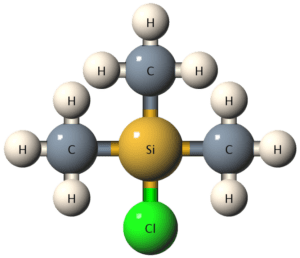

Silanes are a class of chemicals consisting of one or more silicon atoms. What makes silanes attractive to surface chemists is that molecules can be easily engineered to create special bifunctionalities allowing for select organic isomers to be attached to surfaces.

IST’s products are designed to work with a wide range of Silanes ranging from volatile low molecular weights to mid-range melting point solids of molecular weights >5000amu.

IST’s products are designed to work with a wide range of Silanes ranging from volatile low molecular weights to mid-range melting point solids of molecular weights >5000amu.

IST has a proprietary way of “Partial Pressure Dosing” silanes for complete control of the process which allows for 100% repeatability between runs. This allows silianation coatings to be performed at lower temperatures which is critical to bio-consumables or other polymeric materials.

IST’s silanation is also coupled with plasma-based surface preparations. Our plasma technology allows for precision cleaning of the substrate immediately prior to any coating and allows for surface activation, adhesion promotions and decontamination of the surfaces.

IST has a wide range of silane chemistries for demonstration ranging from hydrophobic (perfluoronated and non-fluoronate alkyl chains), hydrophilic (metal oxides like SiO2, TiO2, Al2O3) or PEG’s to reactive films (like amines, epoxies, methacryoxy, aldehydes, Bromos, or vinyls) or bio-compatible films (hydrophobic or mPEG’s).