PECVD (Plasma Enhanced Chemical Vapor Deposition) is a process which uses the energy from a glow discharge (i.e. a plasma) to induce reactions at the surface that would normally require high temperatures. With PECVD, thin films of oxides or polymers can be deposited at room temperature adding another surface modification technique which can be combined with our other advanced vapor-phase surface modification.

PECVD is used to assist in the grafting of special organic molecules to surfaces that are typically inert or unreactive like polymers and plastics.

As an example: – a thin PECVD oxide can deposited at room temperature over a polymer creating an ideal surface for adhesion. Sequentially, the oxide surface can be silanated to create additional functionalities.

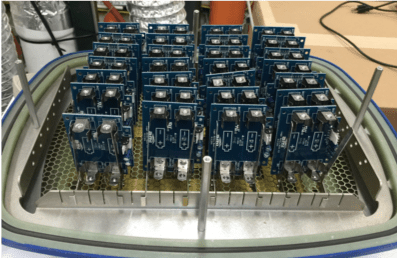

A common technique to create high levels of liquid repellency on entire 3D products is to use PECVD to deposit a nano-scale plasma polymer coating. IST’s Watershield process provides protection spanning from humidity and weather, from splashes and spills and even accidental submersion. We customize our technology to suit specific devices: their target market, performance requirements and levels of potential liquid damage they could be exposed to.