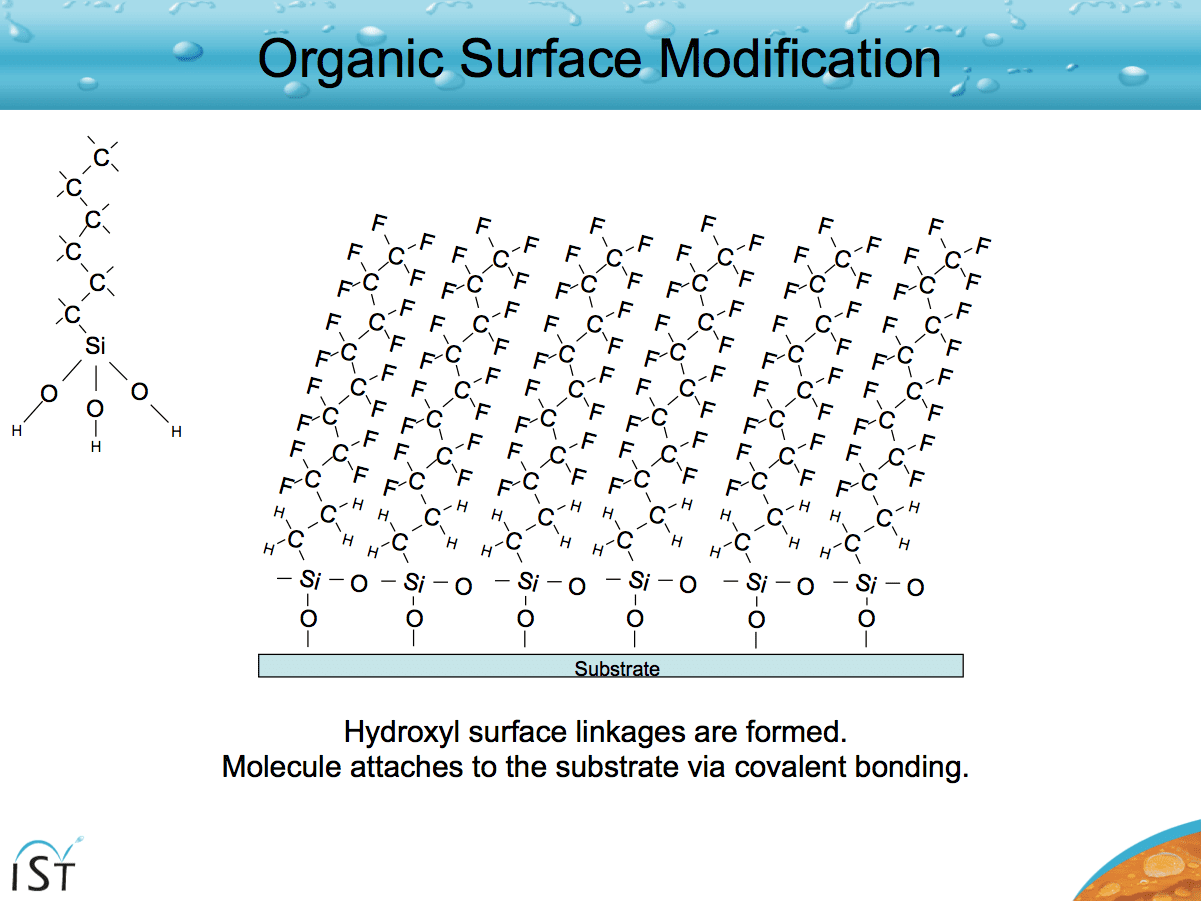

There are many ways to alter the surface properties depending on your needs. With advanced surface modification, the surface energy of a device is tuned to your desired properties. These properties could be hydrophobic, hydrophilic, sticky (reactive functionalities like epoxies or amines) to non-sticky (anti-fouling). Surface modifications can be temporary through the use of gas plasmas for promoting bonding or increased reactivity. Surface modifications can also be permanent with the deposition of a molecular film which is covalently bonded through the use of silane chemicals or by the deposition of an inorganic layer by ALD (atomic layer deposition). In general, surface modification techniques are 100% conformal even down to the atomic level.

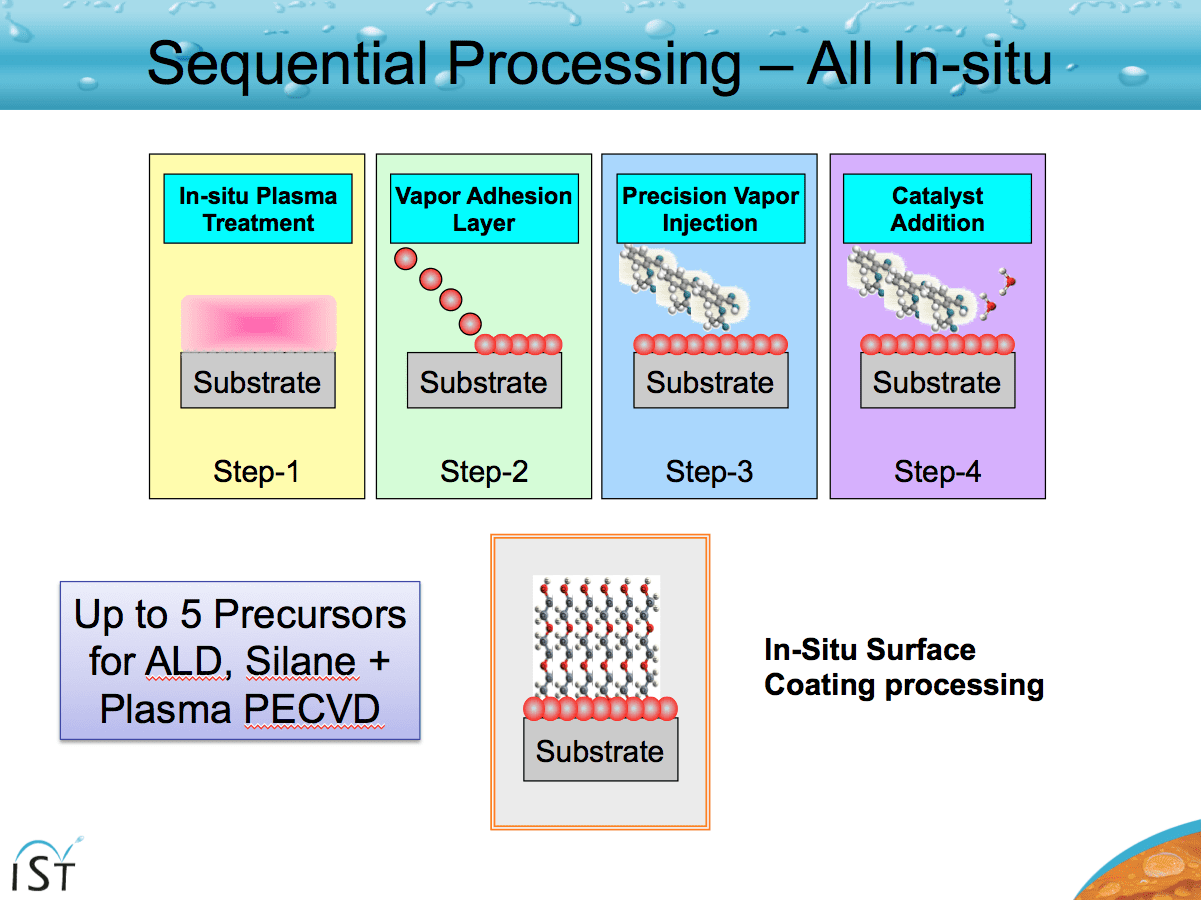

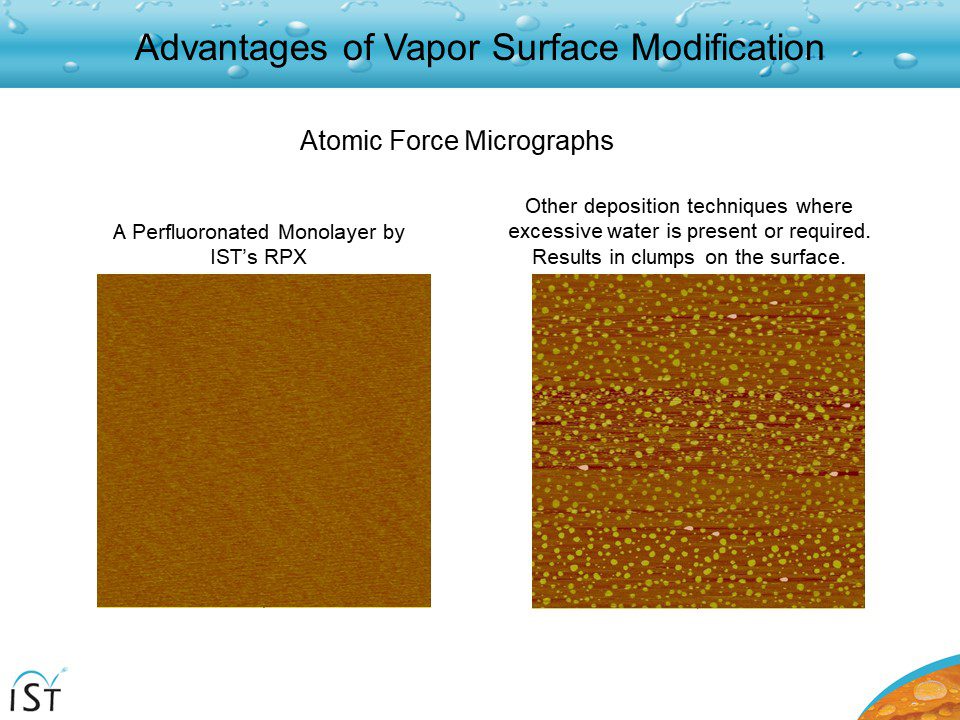

IST’ specializes in the vapor-phase or dry deposition of these films utilizing State-of-the-Art sub-atmospheric based processing equipment. By leveraging years of experience from the Semiconductor Equipment Sector, IST has developed a portfolio of the processing equipment which capitalizes on semiconductor reliability and process control but yet adapting low costs techniques when semiconductor requirements are not needed like using a leak valve versus an electronic mass flow controller. Vapor-Phase processing allows for day-to-day repeatability since the deposition conditions are completely controlled and replicated each run. This also eliminates chemical waste streams typical in a Bio laboratory. While there is an initial capital cost for the vacuum hardware, the cost-of-consumables can be pennies to the dollar since little to no waste of reagents is required saving money in the long run while producing superior films.

Nano-films can range from monolayers (Angstroms (Å) = 10-10 meters) to hundreds of nanometers (10-9 meters) and can be customize depending on the desire goal. A typical film thickness is 5Å to 15Å for a monolayer and up to 2000Å for a nano-composite film customizable to your needs.

Coupling agents using specially selected bi-functional molecules can create adhesive bonds between surfaces and other films. There are a number of chemicals which can selected. For example, many of these films have functional terminations like carboxylic acids, amines, aldehydes, hydroxyls, thiols, epoxies, acrylates, methacrylate, etc.)